| Sign In | Join Free | My tjskl.org.cn |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My tjskl.org.cn |

|

Brand Name : XinYu

Model Number : SK-30/SK32/SK34/SK35

Certification : ISO9001

Place of Origin : China

MOQ : 10Tons

Price : USD100~USD320/Ton

Payment Terms : Western Union, T/T, L/C, D/A, D/P

Supply Ability : 500Tons/month

Delivery Time : 5-8days

Packaging Details : wooden pallet with paper each layer, wrapped with thick paper and PVC film outside.

Shape : Brick,Block,customized

Material : Refractory clay Block,calcined bauxite

Refractoriness (degree) : Common (1350℃); Refractoriness; 1250~1760°)

Application : Industrial Furnaces,Metallurgy,Nonferrous Metal Furnace

Color : Yellow

Al2o3 content (%) : 32%-48%

Clay fire-resistant brick for hot air furnace/High pressure strength,high wear resistance,Low softening temperature unde

Product description:

Clay bricks are made of clay clinker as aggregate and refractory clay (soft clay or semi-soft clay) as binder, and the content of AL2O3 is 30%-48%.It is a kind of refractory product with wide application and huge output.Clay products are acidic refractory products, and the acidity increases with the increase of SiO2 content.It has a certain resistance to acid slag erosion, but the resistance to alkaline slag erosion is poor, so clay products should be used as the lining of acid kiln;Also used in blast furnace, hot air furnace, glass kiln, carbon roasting furnace and other high temperature kiln.

Production process:

The production process of Clay bricks can be divided into as following process:

Raw material mixing, molding, sintering, selection, packing, delivery.

1) Generally, Clay bricks was molded by dry pressing.

2) By means of mixing the material uniformity in proportion and ageing mixture some time. Then, pour some powders into the mold and dry pressing.

3) After dry pressing, the adobe needs to be pushed in the drying kiln to stove or stay in the air to dry. This progress will need about 3-5 days.

4) After this progress, then push the adobe into the tunnel furnace or shuttle kiln to burn around 1300C. This progress will be need about 5-7 days.

5) After burning, the finished Clay bricks will be packed on pallet.

Features:

Resistance to High temperature, Resistance to erosion, resistance to abrasion;

Excellent compression strength;

Resistance to acid and alkali;

Excellent heat stability.

Application:

The Clay bricks are widely applied to industrial furnace, glass furnace, chemical industrial furnace, utility industry furnace lining, smelting furnace, and heat insulation ventilation wall.

Physical and chemical indicators:

| Brand | SK-30 | SK-32 | SK-34 | SK-35 |

|---|---|---|---|---|

| Al2O3/%,≥ | 30 | 35 | 38 | 45 |

| Fe2O3/%,≤ | 2.5 | 2.5 | 2.0 | 2.0 |

| Refractoriness (SK) | 30 | 32 | 34 | 35 |

| Refractoriness under load,0.2MPa,℃(≥) | 1250 | 1350 | 1370 | 1420 |

| Apparent porosity | 22-26 | 20-24 | 20-22 | 18-20 |

| Bulk density | 1.9-2.0 | 1.95-2.2 | 2.1-2.23 | 2.15-2.24 |

| Crushing strength,≥ | 20 | 25 | 30 | 40 |

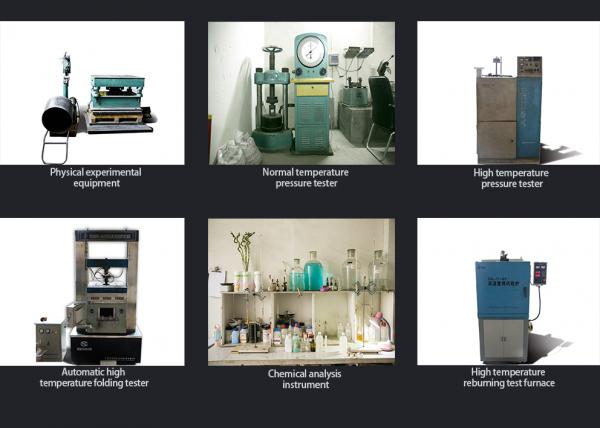

Production and inspection :

Packaging and transportation:

|

|

Clay Fire Resistant Bricks , Common Burnt Clay Bricks High Pressure Strength Images |