| Sign In | Join Free | My tjskl.org.cn |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My tjskl.org.cn |

|

Brand Name : ZHENGZHOUXINYU

Model Number : XY-ZL-50/60/65/70/75

Certification : GB/T19001-2016/ISO9001:2005

Place of Origin : ZHENGZHOUGONGYI

MOQ : 2T

Price : 380USD~760USD/T

Payment Terms : L/C, , T/T, D/P, Western Union, MoneyGram

Supply Ability : 1000/T/3D

Delivery Time : 4-6work Days

Packaging Details : Container bag

AL2O3 content(%),≥ : 50/60/65/70/75

Size : 0-3mm,10%/3-5mm,42%/5-8mm,40%/8-15mm,8%

Refractoriness(degree) : 1770℃<Refractoriness<2000℃

Application : Roof,wall,and partition in the preheat area

Bulk density/ g﹒cm-3,≥ : 2.25~2.6 g﹒cm-3(110℃)

Permanent linear change/% : ±0.5

Water requirement/% : 6-7/5-6

Self flowing castables/For industrial kilns/Easy installation, good anti-spalling and thermal shock resistance

Product description:

Using high quality bauxite and mullite as the main materials, the ultrafine powder bonded low cement castables for furnace lining are characterized with good flow ability, easy installation, good anti-spalling and thermal shock resistance, low thermal expansion, and good thermal insulation. The products can be widely used at roof, wall and bottom for industrial furnaces.

Self flowing castables

With vibrating-free or lightly vibrating, these castables can degas and densificate by self-gravity.These products can ban installed by pumping,and characterized with high strength and good thermal shock resistance.

Category of Refractory Castable:

Features:

They are characterized with good installation, excellent slag erosion resistance and thermal shock resistance, and gain good performance.

Physical and chemical indicators:

| Brand | XY-ZL-50 | XY-ZL-60 | XY-ZL-65 | XY-ZL-70 | XY-ZL-75 |

|---|---|---|---|---|---|

| Al2O3/%,≥ | 50 | 60 | 65 | 70 | 75 |

| Bulk density/ g﹒cm-3,≥ | 2.25 (110℃,24h) | 2.35 (110℃,24h) | 2.4 (110℃,24h) | 2.5 (110℃,24h) | 2.6 (110℃,24h) |

| Crushing strength/ MPa,≥ | 30 (110℃,24h) | 35 (110℃,24h) | 35 (110℃,24h) | 40 (110℃,24h) | 40 (110℃,24h) |

| 40 (1300℃,3h) | 40 (1400℃,3h) | 45 (1400℃,3h) | 45 (1400℃,3h) | 50 (1500℃,3h) | |

| Permanent linear change/% | ±0.5 (1300℃,3h) | ±0.5 (1400℃,3h) | ±0.5 (1400℃,3h) | ±0.5 (1400℃,3h) | ±0.5 (1500℃,3h) |

| Water requirement/% | 6-7 | 6-7 | 6-7 | 6-7 | 5-6 |

| Max service temperature/℃ | 1300 | 1400 | 1400 | 1400 | 1500 |

| Application | Roof,wall,and partition in the preheat area | Roof,wall,and partition in the heating area | |||

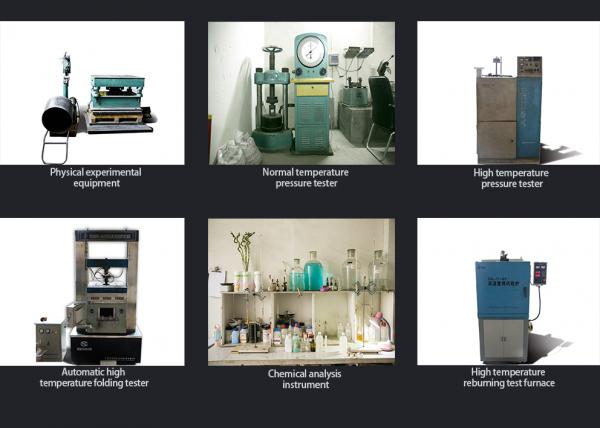

Production and inspection :

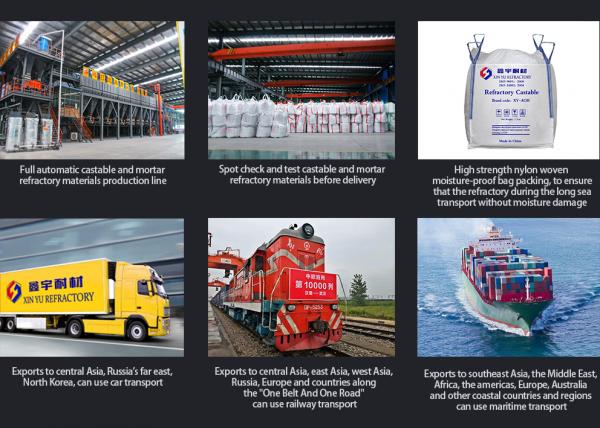

Packaging and transportation:

|

|

Self Flowing Castable Refractory Material Easy Installation For Industrial Kilns Images |